In the hustle and bustle of our everyday lives, we seldom stop to think about the intricate processes behind the objects and tools we rely on. From the chair we sit on at breakfast to the car we drive to work, many of these items owe their existence to CNC turning, a highly advanced manufacturing technology. CNC turning shapes metals and plastics into precise, essential components that power our devices, equipment, and vehicles. Without this technology, the world we live in would look and function very differently.

Radmot, a company specializing in https://radmot.com/blog/cnc-milling, is at the forefront of this technology, creating high-quality components for industries across the board. Their expertise ensures that the products we use are manufactured to perfection, contributing to a world where precision and reliability are non-negotiable. Whether you’re aware of it or not, CNC turning is a technology that’s shaping the world around you every day.

Understanding CNC Turning: The Technology Behind the Process

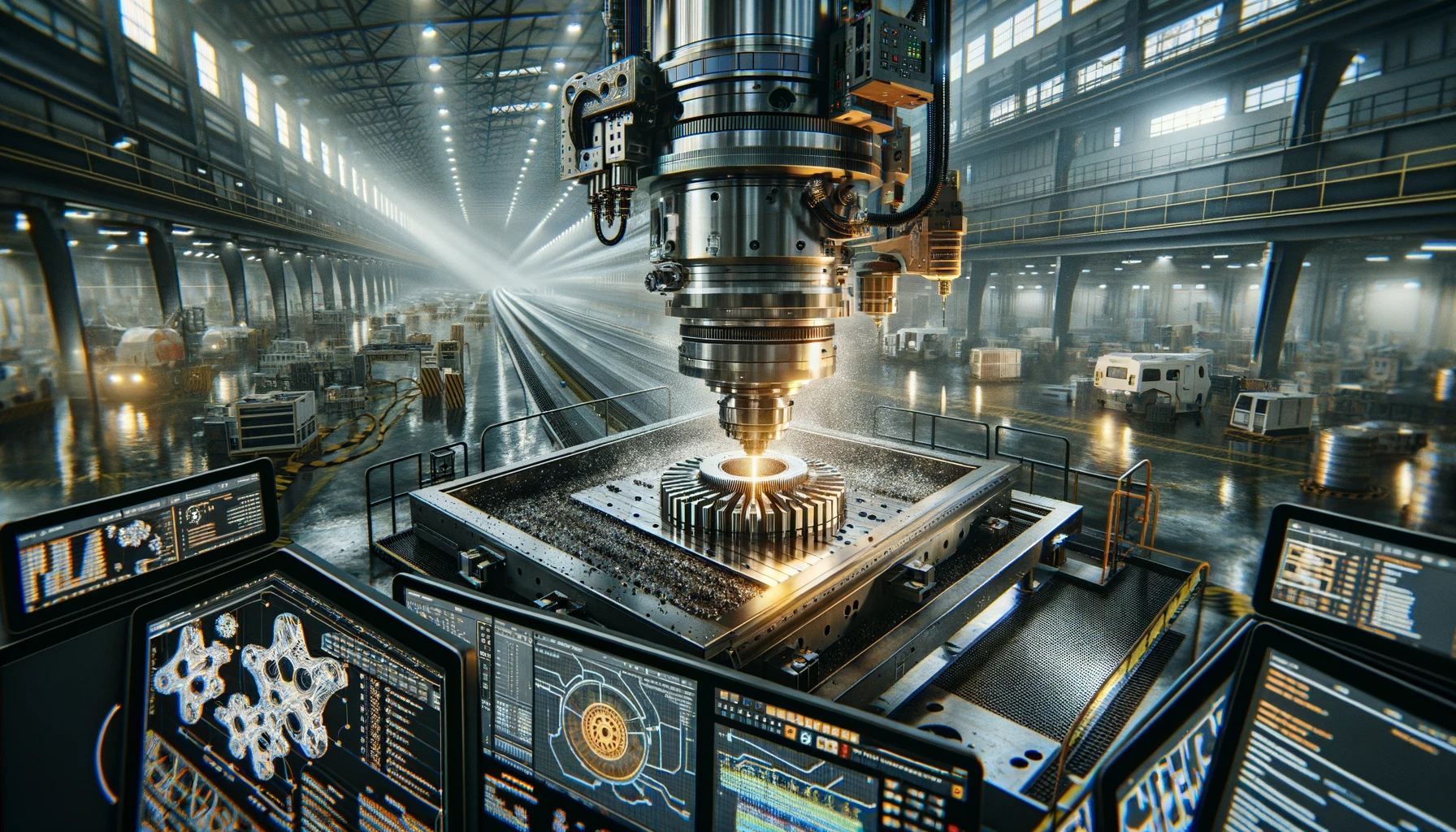

CNC turning stands for Computer Numerical Control turning, which refers to the automated process of machining parts. In simple terms, this technology allows machines to produce precision parts by removing material from a workpiece as it rotates on a lathe. A computer program guides the machine, ensuring every cut and movement is calculated with exceptional accuracy. This process is ideal for creating round or cylindrical parts, such as screws, bolts, shafts, and gears.

The beauty of CNC turning is its ability to replicate the same design multiple times with the exact same level of precision. Human error is almost completely eliminated because the machine follows the computer’s commands without deviation. This leads to perfectly uniform parts, whether the order is for a single prototype or a mass-produced batch.

Radmot’s CNC turning capabilities stand out due to their attention to detail and commitment to quality. Their use of advanced machinery ensures that each component, no matter how small, is crafted with care and precision. With Radmot, industries ranging from automotive to aerospace can rest assured that the parts they receive will meet the highest standards.

How CNC Turning Enhances Everyday Products

Though it might not be obvious, CNC turning plays a key role in the production of many items we use on a daily basis. For example, the faucet in your kitchen, the bolts holding your furniture together, and the components in your car’s engine have all likely been created using CNC turning. This process ensures that each part is made to exact specifications, resulting in a product that is reliable, safe, and long-lasting.

Let’s take a closer look at the car you drive. When you close the door or turn the ignition, you’re interacting with dozens of parts that were made using CNC turning. Engine components, such as pistons, camshafts, and bearings, are crucial to the car’s performance, and even the smallest flaw could cause a malfunction. CNC turning’s precision ensures that these parts are made to fit perfectly, minimizing the risk of error and extending the life of your vehicle.

In the realm of home appliances, CNC turning also plays a significant role. Consider the coffee maker you use every morning. Inside, there are numerous small components that need to work together seamlessly to brew your coffee. These parts are often made of stainless steel or aluminum and are manufactured using CNC turning to ensure they fit precisely and function efficiently. Thanks to this technology, you can count on your coffee maker to deliver the perfect cup every time.

At Radmot, CNC turning is used to create components for a wide variety of industries, all with the same level of precision and quality. Whether it’s a small, intricate part for an electronic device or a larger component for industrial machinery, Radmot ensures that each piece meets the exacting standards required for modern manufacturing.

Radmot: Pioneering Precision in CNC Turning

As industries evolve and demand for precision increases, companies like Radmot are rising to the challenge by perfecting the art of CNC turning. Their state-of-the-art equipment and expertise allow them to produce components that meet the strictest tolerances, ensuring that every product functions as intended. This is particularly important in industries such as aerospace, medical, and automotive, where even the slightest flaw could have serious consequences.

Radmot’s dedication to quality goes beyond just meeting technical specifications. They understand that in today’s world, customers expect more than just functional products—they expect reliability, safety, and longevity. By using CNC turning, Radmot can produce components that not only work well but are also built to last. This means fewer malfunctions, less wear and tear, and ultimately, greater customer satisfaction.

Moreover, Radmot is committed to innovation in the field of CNC turning. They are constantly updating their machinery and refining their processes to stay ahead of the curve. As new technologies emerge and industries grow more complex, Radmot is ready to meet the challenge with cutting-edge solutions that ensure their clients receive the best possible products.

The Future of CNC Turning and Its Impact on Industries

Looking ahead, CNC turning will continue to play an increasingly important role in modern manufacturing. As industries like robotics, aerospace, and medical devices expand, the demand for precision-engineered parts will grow. CNC turning offers the flexibility and precision needed to create the highly specialized components these industries require. From tiny, intricate parts for robotic arms to large, durable pieces for industrial machines, CNC turning will be essential for the future of manufacturing.

Radmot is well-positioned to lead the way in this evolving landscape. Their expertise in CNC turning, coupled with their commitment to innovation, ensures that they will continue to provide the high-quality components that modern industries rely on. As the world becomes more reliant on technology and automation, CNC turning will remain a cornerstone of the manufacturing process, and companies like Radmot will be at the forefront of this transformation.

Conclusion: CNC Turning’s Role in Shaping Our World

CNC turning may not be something we think about daily, but it has a profound impact on the way our world functions. From the vehicles we drive to the appliances we use, this technology ensures that the products we rely on are made with precision, reliability, and care. Radmot, with its expertise in CNC turning, plays a vital role in creating the components that make our lives easier and more efficient.

As industries continue to innovate and evolve, CNC turning will remain a critical part of the manufacturing process, ensuring that the products of tomorrow are built with the same precision and quality that we’ve come to expect today. With Radmot leading the charge, the future of CNC turning looks bright, and the products we use every day will continue to be safer, more reliable, and more efficient than ever before.